Lamasan, which was founded in 1981 by ancient printer and installer Ahmet Pehlivan is managing children today. organization was established after extensive reasearch of 5 years printing house started producing large knives and has addressed major deficiencies.

Over time it has extended its services by wood industry (particleboard, fiberboard, veneer, plywood, matches, etc.), paper, chemical industry (plastics, rubber, etc.) iron industry (steel cutting blades), tobacco breaking blades, textile industry (textiles, silk carpet, etc.), food industry (ice cream, cattle body separation knife, dough scraper blade etc.), banknotes cutting blades and packaging knives

The knives are made in two separate production method.

Bıçaklarda iki ayrı yöntemle üretim yapılmaktadır.

* Solid cutting knives

* Brazing and produced with two different steel knives

* Yekpare kesici bıçaklar

* Set lehim (brazing) ile üretilmiş iki farklı çelik içeren bıçaklar

Only in the printing area there are 200 different types and sizes (up to 2m long) laman (cutting edge) series continues its production. Before pet up for sale all products undergo quality controls and guaranteed for one year. Special orders are taken.

LAMAS has appreciated background In the manufacture of machinery. Headlines that made are gathered under.

*Electro magnetic surface grinding machine used for different purposes: 18 cm width and 2m tall blades (steel) serves grinding.

Cardboard scissors; furnishers fillet name in the use of machines; 100 cm length is cut veneer, plastic, cardboard, sheet metal up to 0.55mm thickness is cut. Binding Lera from handbags, belts (leather) until the market has a variety of manufacturers. One is to make a single cut.

* Waste paper baling press (which has 10 tons of clamping force. Raises bales 70x100x70 cm.)

* Great small printing machines; past numerous and quite time sewing machine using produce the copper wire (which is produced in Turkey still many years ahead of the firms in the industry Ahmet Pehlivan first established by the first time itself.), automatic bookbinding presses, passing tin on the calendar machine, typesetter break the automatic coil cutting size (making paper sheet) like machines.

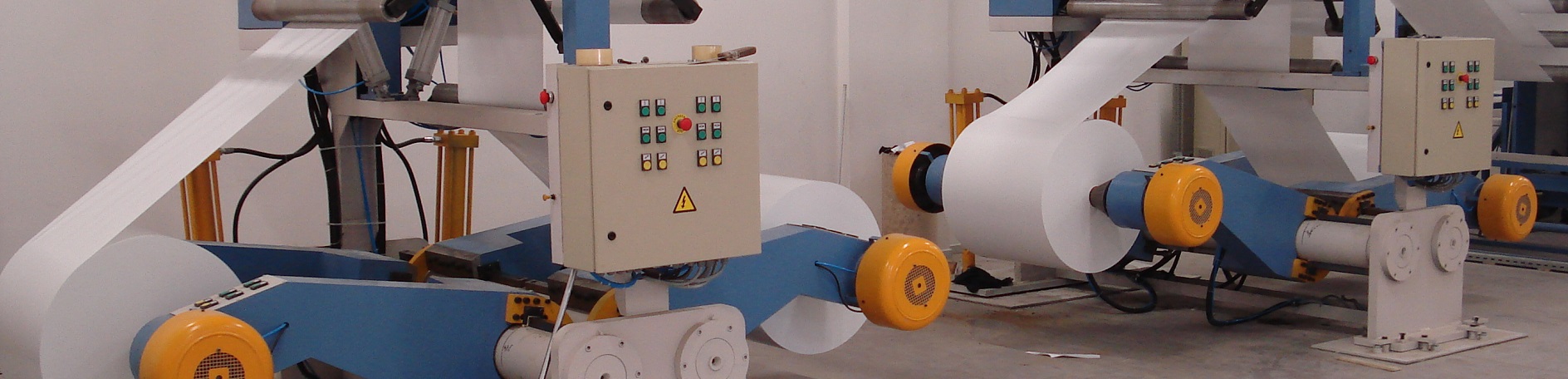

* Between years 1995-1996 the advanced activities for the production of machinery has continued for AR-GE. I can not help saying that the way we see great benefit in setting a point. The release of the research is done prior to any anniversary Ahmet Pehlivan, it has become the corporate culture in LAMASAN. However, Turkey's first precedent in the world of machines and single coil cutting machines are the fastest was launched in 1997. The design is made entirely by UNAL and AHMET PEHLİVAN.

* Semi electronically controlled coil paper sizing machine; paper reckoning output cut in desired sizes and band together to take the desired quantity. Dimensions makes cut in standard sizes used in printing is being implemented with the gear. Balta's speed is 350 rev / min. Max capacity of 1400 sheets / min.

Modem connection can also be made. Sizes are set by the help of computer. Speacial cut can be done with the limits of 400-1200 mm size. Balta's speed is 400 rev / min. Max capacity of 1600 sheets / min. Four coils implantable coil cutting machines are 1050 mm width 1200 mm and can be made clear cutting all kinds of paper (3 dough, 1 dough, coated paper, cardboard etc.) are cut feature.

MARBLE TILE-band polishing machines that we made between the year 1988-1998 has been preffered brand in pur contry and abroad with their quality. 6 different types of marble according to its purpose (gezerl) and tiles (fixed) has produced and tile cleaning machines and equipment back to erase.

Robotic tiles behind erase:

2 of 5 diamond abrasive head 40 cm in width

3 of 5 diamond abrasive head 40 cm in width

8 3 diamond abrasive head 40 cm in width

2 diamond abrasive head 8 to 60 cm in width

8 3 diamond abrasive head 60 cm in width

They make clear the tiles in 11 minutes, 330 cm as polished marble surface raises. 45 m2 / hour capacity.

* In addition, industrial machines are manufactured upon request.

* Machining; Depending on market demand lathes, milling machines, construction machinery parts and precision grinding operations; game machines and molds for smelters, dry ice production equipment molds, CNC machines for processing molds, die casting molds for the tiles.

* Asas Amb. 0.5mm steel container knife cutting machine

* METU ball mill for the Department of Metallurgy and Materials Engineering, rapid solidification rolling, pressing, glove box and so on. laboratory machines are manufactured.

Quick Menu

Manufactoring Machine

Customer Support

0312 354 69 58

Kocasinan Sanayi Sitesi 1187. Sokak No:9 Ostim/ANKARA